In recent years, 3D printing has revolutionized the manufacturing industry, enabling the creation of complex and customized objects with unprecedented ease. Also known as additive manufacturing, 3D printing has evolved to encompass a wide range of technologies and materials. In this article, we will delve into the various types of 3D printing, exploring their unique characteristics, applications, and potential for the future.

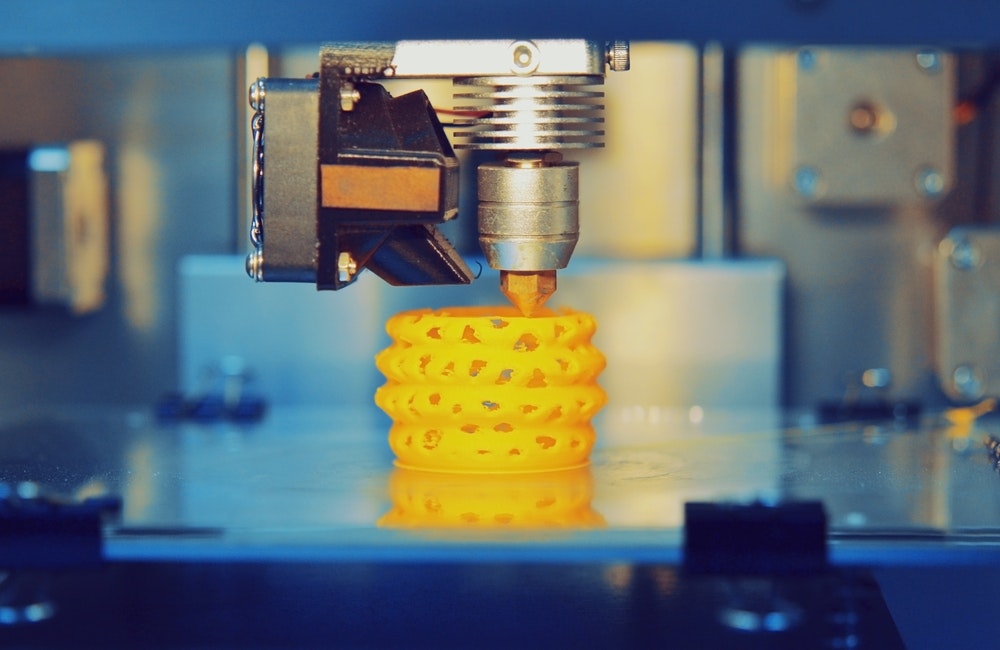

- Fused Deposition Modeling (FDM):

FDM is one of the most common and accessible types of 3D printing. It involves the extrusion of a thermoplastic filament through a heated nozzle, which deposits layers of material to build the object. FDM offers versatility in material choices, including ABS, PLA, and nylon, making it suitable for prototyping, functional parts, and even artistic creations. Its affordability and ease of use have contributed to its widespread adoption in various industries. - Stereolithography (SLA):

SLA utilizes a liquid resin that solidifies when exposed to a specific wavelength of light, typically ultraviolet (UV) light. A build platform gradually lifts the object out of the resin tank as each layer is cured. SLA excels in producing high-resolution, intricate models with smooth surface finishes, making it ideal for applications such as jewelry, dental models, and concept design. Its precision and ability to create complex geometries have made SLA a popular choice in industries that require fine details. - Selective Laser Sintering (SLS):

SLS employs a high-powered laser to selectively fuse powdered materials, such as nylon, into solid objects. The laser scans the powdered bed, selectively melting the particles together to form each layer. SLS offers excellent mechanical properties, making it suitable for functional prototypes, end-use parts, and even aerospace components. Its ability to work with a wide range of materials, including metal powders, expands its potential for advanced applications. - Digital Light Processing (DLP):

DLP is similar to SLA but uses a digital light projector to cure an entire layer of resin simultaneously. This technology enables faster printing speeds compared to SLA. DLP is often favored for applications that require rapid prototyping, such as product design iterations and concept validation. Its speed and cost-effectiveness make it a valuable tool for industries seeking quick turnaround times. - Binder Jetting:

Binder Jetting involves selectively depositing a liquid binder onto a powdered material, layer by layer, to create the desired object. This technique is particularly advantageous for printing large-scale objects or multiple parts simultaneously. Binder Jetting is commonly used in the production of sand molds and cores for metal casting, architectural models, and even food products. Its ability to work with a wide range of materials, including metals and ceramics, makes it a versatile option.

Conclusion:

The world of 3D printing is vast and continually evolving, with new technologies and materials pushing the boundaries of what is possible. From FDM and SLA to SLS, DLP, and Binder Jetting, each type of 3D printing offers unique advantages and applications. As additive manufacturing continues to advance, it holds immense potential for industries ranging from healthcare and aerospace to automotive and consumer goods. Embracing these diverse types of 3D printing opens up a world of possibilities, enabling innovation, customization, and efficiency in manufacturing processes.