Mechanical seals are an essential component of pumps used in various industries, including oil and gas, chemical, and water treatment. They are designed to prevent leakage of fluids and gases from the pump, ensuring efficient and safe operation. In this article, we will explore the reasons why mechanical seals are preferred over other sealing methods and the benefits they offer.

Section 1: What are Mechanical Seals?

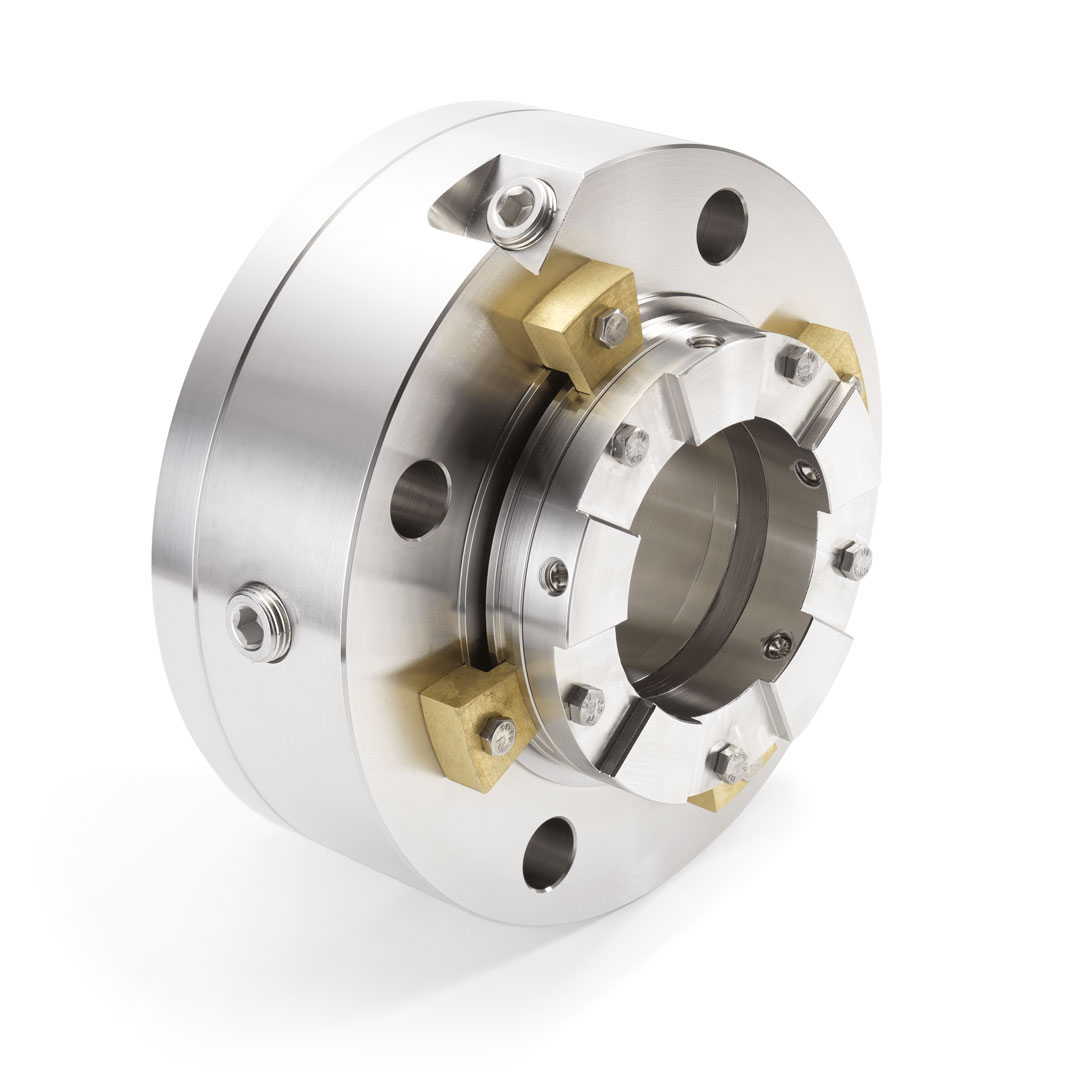

Mechanical seals are devices that create a seal between two surfaces, preventing the leakage of fluids and gases. They consist of two main components: a stationary part and a rotating part. The stationary part is attached to the pump housing, while the rotating part is attached to the pump shaft. When the pump is in operation, the rotating part rotates with the shaft, and the stationary part remains fixed, creating a seal between the two surfaces.

Section 2: Why Use Mechanical Seals for Pumps?

There are several reasons why mechanical seals are preferred over other sealing methods for pumps:

- Improved Efficiency: Mechanical seals offer better sealing performance than other sealing methods, such as packing and gaskets. This results in improved pump efficiency, reduced energy consumption, and lower operating costs.

- Reduced Leakage: Mechanical seals are designed to prevent leakage of fluids and gases from the pump. This reduces the risk of environmental contamination, improves safety, and ensures compliance with regulatory requirements.

- Longer Life: Mechanical seals are designed to withstand high pressures, temperatures, and abrasive fluids. This results in longer seal life, reduced maintenance costs, and increased pump reliability.

- Easy Installation: Mechanical seals are easy to install and require minimal maintenance. This reduces downtime and improves overall pump availability.

Section 3: Types of Mechanical Seals

There are several types of mechanical seals available, including:

- Single Mechanical Seals: These seals consist of a single set of sealing faces and are suitable for low-pressure applications.

- Double Mechanical Seals: These seals consist of two sets of sealing faces and are suitable for high-pressure applications.

- Cartridge Mechanical Seals: These seals are pre-assembled and can be easily installed without the need for special tools or equipment.

- Split Mechanical Seals: These seals are designed to be installed without removing the pump from the system, reducing downtime and maintenance costs.

Conclusion:

Mechanical seals are an essential component of pumps used in various industries. They offer several advantages over other sealing methods, including improved efficiency, reduced leakage, longer life, and easy installation. By choosing the right type of mechanical seal for your pump, you can ensure safe, efficient, and reliable operation.