In the realm of electrical control systems, the choice between solid-state relays (SSRs) and mechanical relays has always been a topic of discussion. Both serve the purpose of switching electrical circuits, but they differ significantly in terms of construction, operation, and performance. This article aims to delve into the intricacies of SSRs and mechanical relays, highlighting their differences and shedding light on the advancements offered by SSRs.

- Construction and Working Principle:

Mechanical Relays:

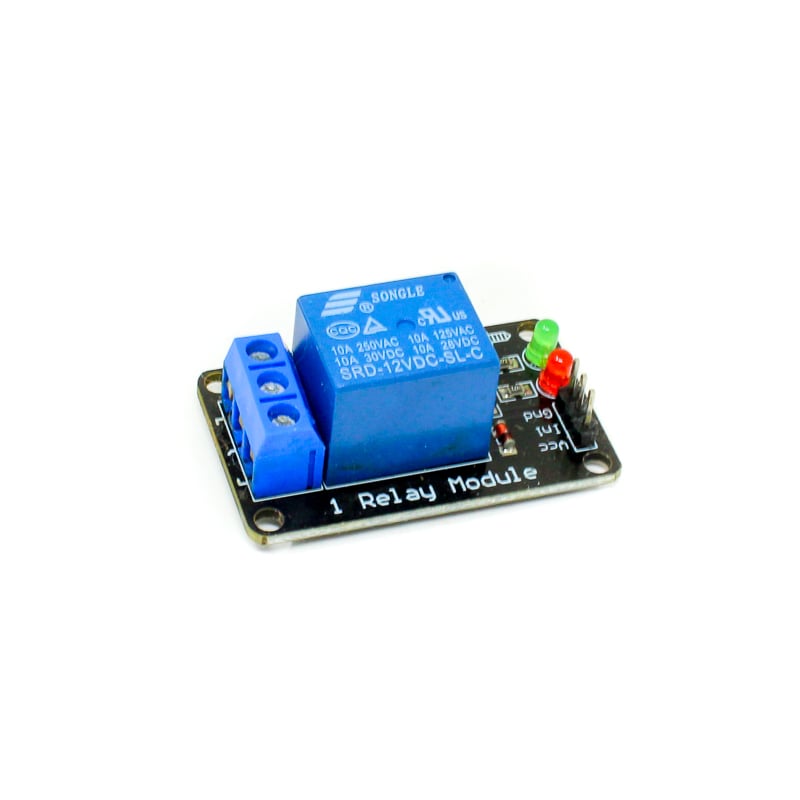

Mechanical relays consist of an electromagnet, an armature, and a set of contacts. When an electrical current passes through the coil, it generates a magnetic field that attracts the armature, causing the contacts to close or open, depending on the relay type. This physical movement of components is the defining characteristic of mechanical relays.

Solid-State Relays:

SSRs, on the other hand, are semiconductor devices that utilize optocouplers, triacs, or thyristors to perform the switching action. They lack any moving parts, making them more reliable and durable than mechanical relays. SSRs operate by using an input signal to trigger the optocoupler, which then activates the semiconductor switch, allowing current to flow through the output circuit.

- Performance and Advantages:

a. Speed and Response Time:

SSRs have a distinct advantage over mechanical relays when it comes to speed and response time. Due to their solid-state nature, SSRs can switch on and off much faster, typically in microseconds. Mechanical relays, on the other hand, have inherent mechanical limitations, resulting in slower switching times, usually in milliseconds.

b. Noise and Vibrations:

Mechanical relays produce audible clicks and vibrations during operation due to the physical movement of components. This can be undesirable in certain applications, such as audio systems or sensitive equipment. SSRs, being solid-state devices, operate silently without any vibrations, making them suitable for noise-sensitive environments.

c. Lifespan and Reliability:

The absence of moving parts in SSRs contributes to their extended lifespan and enhanced reliability. Mechanical relays are prone to wear and tear, leading to eventual failure over time. SSRs, with their solid-state design, can withstand millions of switching cycles, ensuring longevity and reducing maintenance requirements.

d. Size and Compactness:

SSRs are significantly smaller and more compact than mechanical relays. This compactness allows for higher density mounting on circuit boards, making them ideal for space-constrained applications. Mechanical relays, due to their larger size and physical components, occupy more space and limit design flexibility.

- Applications:

a. Industrial Automation:

SSRs find extensive usage in industrial automation systems, where their fast switching speed, reliability, and noiseless operation are highly valued. They are commonly employed in motor control, robotics, and process control applications.

b. HVAC Systems:

Mechanical relays have traditionally been used in heating, ventilation, and air conditioning (HVAC) systems. However, SSRs are gaining popularity in this domain due to their compact size, silent operation, and ability to handle high currents.

c. Medical Equipment:

The reliability and long lifespan of SSRs make them suitable for critical medical equipment, such as patient monitors, diagnostic devices, and surgical instruments. Their noiseless operation is also beneficial in maintaining a calm and comfortable environment for patients.

Conclusion:

In summary, the difference between SSRs and mechanical relays lies in their construction, operation, and performance characteristics. SSRs offer advancements in terms of speed, reliability, compactness, and noiseless operation. While mechanical relays still have their place in certain applications, the growing popularity of SSRs in various industries showcases their superiority in many aspects. As technology continues to evolve, it is essential to stay informed about these advancements and make informed decisions when selecting relays for specific applications.